Technical Information

Technical Information Power And Control Cables

Power And Control Cables Power Appendixes

Power Appendixes Fire Performance of Cable

Fire Performance of Cable  KCI Low Smoke Cable Certifcates

KCI Low Smoke Cable Certifcates صفحه KCI Low Smoke Cable Certifcates

|

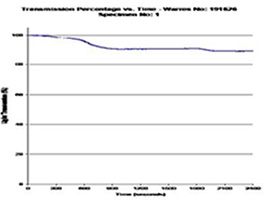

KCI Low Smoke Cable Certifcates Low smoke cable acc to BS EN 61034-2: 2005 : Purpose of test : To determine the performance of a specimen of a cable when it is subjected to the conditions of the test specifed in BS EN 61034-2: 2005: “Measurement of smoke density of cables burning under defned conditions”. The test was performed in accordance with the procedure specifed in BS EN 61034-2: 2005 and this report should be read in conjunction with that Standard. Scope of test BS EN 61034-2: 2005, details a method of test for the measurement of the density of smoke emitted from cables burning under the defned conditions of the test. The result is expressed as percentage light transmittance and is used to determine compliance with the criterion given in Section 7 of the Standard. Test results :Two specimens were tested. |

|

|

Specimen No Minimum light transmittance (%) 1 89.11 2 86.41 Average minimum light transmittance 87.76% |

|

|

|

|

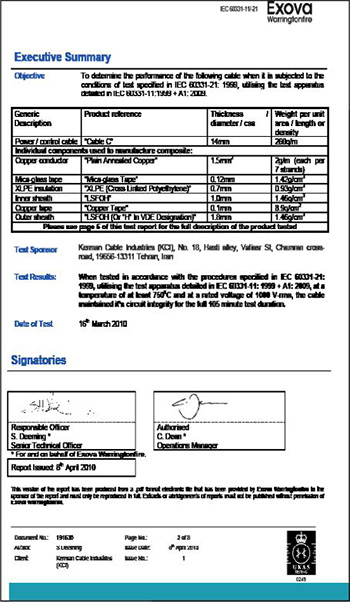

Determining the circuit integrity of electric cables under fre conditions ; IEC 60331-11 / -21: Purpose of test : To determine the performance of a specimen of a cable when it is subjected to the conditions of test specifed in IEC 60331-21: 1999, utilising the test apparatus detailed in IEC 60331-11:1999 + A1: 2009. The purpose of this test method is to determine whether a cable can maintain circuit integrity when it is exposed to the fre conditions described within the method. Scope of test : IEC 60331-21: 1999 specifes a test procedure and gives a performance requirement, including a recommended fame application time, for cables of rated voltage up to and including 600/1000 V. It is intended to cover low voltage power cables and control cables with a rated voltage. In accordance with section 7.1 of the test standard, a 90 minute fame application time was used. |

|

|

Results of test : When tested in accordance with the procedures specifed in IEC 60331-21: 1999, utilising the test apparatus detailed in IEC 60331-11: 1999 + A1: 2009, at a temperature of at least 750 0C and at a rated voltage of 1000 V-rms, the cable maintained it’s circuit integrity for the full 105 minute test duration. (Consisting of a 90 minute fame application period,plus a 15 minute cool down period). |

|

|

|

|

|

|

|

|

IEC 60754-1 & 2 Tests on Outer Sheath :

|

|

|

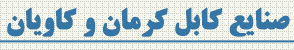

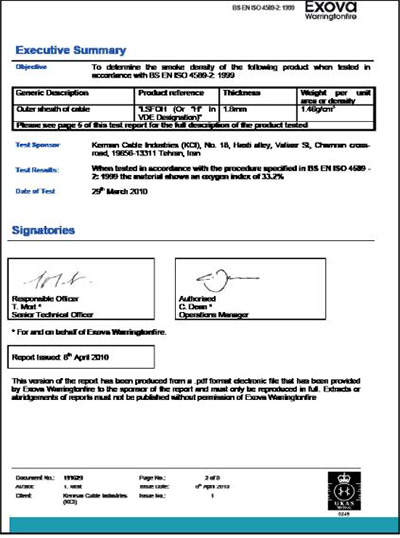

ISO 4589-2 (for improved fame retardancy verifcation) Tests on Outer Sheath :

|

|